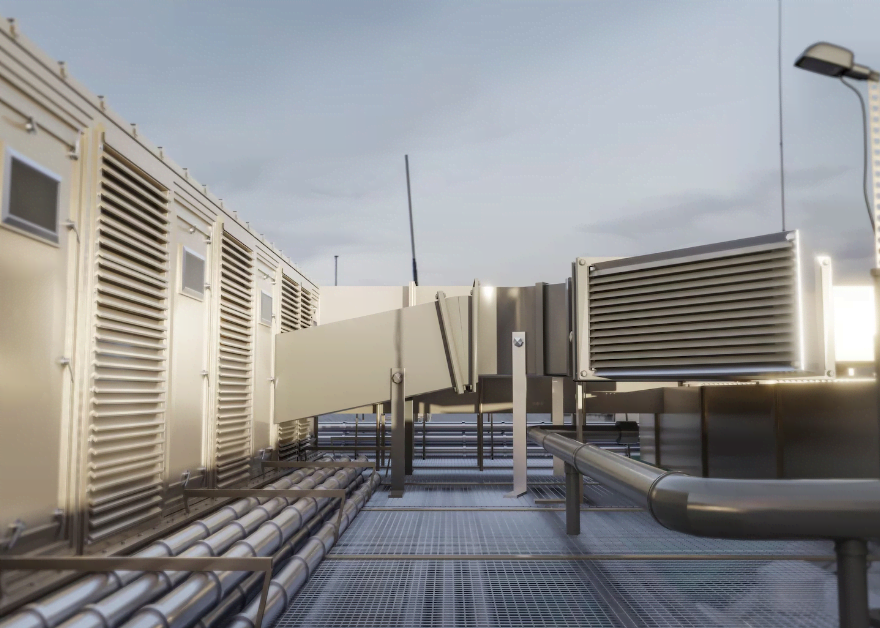

Chiller Service

Chiller systems are indispensable for meeting cooling needs in industrial and commercial areas. These systems play a critical role in production processes, large buildings, and many industries. So, why is chiller system maintenance so important? This is where a significant difference can be made. Without maintenance, systems lose efficiency, leading to high energy costs.

The benefits of chiller service include extending the system’s lifespan and preventing breakdowns. Regular maintenance improves system performance, allowing businesses to achieve greater efficiency with less energy consumption. Remember, a properly functioning chiller system not only saves costs but also reduces environmental impact.

Are you curious about how chiller service works? Typically, a service technician inspects all components of the system. Refrigerant levels, filters, compressors, and more are examined. This process is critical for assessing the overall health of the system and provides a great opportunity for early detection of faults.

There are several points to consider when choosing a chiller service. The provider’s experience, references, and warranties are very important. A quality service not only solves immediate problems but also offers a long-term partnership. Therefore, research carefully to make the right choice.

Importance of Chiller Systems

Chiller systems play a vital role in industrial and commercial fields. These systems ensure smooth production processes by meeting cooling requirements. Imagine running a factory—if the chiller system doesn’t work properly, product quality drops, costing you both time and money. That’s why keeping chiller systems in good condition is crucial.

In terms of energy efficiency and cost savings, the importance of chiller systems cannot be overlooked. A properly functioning chiller reduces energy consumption, which significantly lowers utility bills. For instance, a regularly maintained chiller system can consume 20% less energy, resulting in substantial long-term savings.

Moreover, chiller systems are essential for businesses aiming to adopt an eco-friendly approach. Systems built with the right materials reduce carbon emissions, helping protect nature while enhancing business sustainability.

In summary, chiller systems do more than provide cooling. They also deliver key benefits such as energy efficiency, cost savings, and environmental protection. Therefore, regular inspections and maintenance of your chiller systems are critical steps for your business success.

Chiller Maintenance Processes

Chiller systems are crucial for achieving energy efficiency in industrial and commercial spaces. Regular maintenance is essential for their proper operation. So, how do chiller maintenance processes work? The answer is vital for both reducing costs and extending system lifespan.

The maintenance process generally involves several stages. It begins with a visual inspection to check for any external abnormalities. Next, internal components such as refrigerant levels and filter conditions are examined. During this phase, attention should be given to the following elements:

- Filter Cleaning: Dirty filters reduce system efficiency.

- Refrigerant Check: Insufficient refrigerant levels negatively affect system performance.

- Electrical Connections: Loose connections can cause malfunctions.

Maintenance should generally be performed at least once a year, though in cases of heavy use, this period may be shorter. Experts note that regular maintenance can improve system efficiency by up to 20%, reducing energy consumption and minimizing breakdown risks.

In conclusion, chiller maintenance processes are indispensable for ensuring system health. Remember, a neglected system can lead to bigger problems later on. Therefore, don’t skip maintenance schedules—always rely on professional service.

Chiller Fault Detection

Detecting faults in chiller systems is of critical importance for timely intervention. These systems play a major role in cooling operations, and any issue can quickly escalate. So, how can such faults be identified? Here are some key points:

First, visible signs can be telling. Noise, leaks, or abnormal temperatures indicate a problem within the system and should not be ignored. A drop in system performance is another indicator of malfunction. For example:

- Reduced cooling capacity

- Unexpected increase in energy consumption

- Fluctuating frequencies

Regular maintenance is also crucial for fault detection. During maintenance, all parts of the system are inspected, and potential issues are identified early. This helps prevent major breakdowns in the future. Maintenance processes typically include the following stages:

| Stage | Description |

|---|---|

| Visual Inspection | External examination of system components. |

| Performance Test | Measuring cooling capacity and energy consumption. |

| Cleaning | Cleaning filters and other components. |

Finally, if you detect a fault, contact a professional technician immediately. Remember, early intervention always saves costs and extends the system’s lifespan. Be proactive to maintain your chiller system’s health!

Key Factors When Choosing a Chiller Service

There are several important factors to consider when selecting a chiller service. These factors are key to receiving quality service. First, experience is crucial. The provider’s years of industry experience inspire confidence. Remember, an experienced team can identify and fix problems more quickly and effectively.

Another important factor is references. Feedback from previous clients can give insight into the quality of service. If possible, contact a few references to learn from their experiences—this can help you make the right decision. Additionally, warranties should be considered. A service provider’s warranty reflects the quality of their work and allows easy resolution in case of problems.

The provider’s certifications and training level also matter. A certified team adheres to industry standards, enhancing safety. Moreover, customer service quality should not be overlooked—a team that responds quickly and effectively to inquiries can help manage issues more easily.

Finally, pricing is an important factor. However, instead of focusing solely on the lowest price, evaluate the value offered for the cost. Choosing cheap but low-quality service can lead to higher expenses in the long run. Therefore, strike a good balance between price and quality.

FAQ (Frequently Asked Questions)

- Why is chiller system maintenance important?Chiller systems play a critical role in providing energy efficiency and cost savings in industrial and commercial areas. Regular maintenance improves system performance and prevents failures.

- How often should chiller maintenance be performed?The maintenance process should be performed at least once a year. However, depending on usage intensity, this interval may vary. Experts recommend more frequent maintenance based on the system’s condition.

- What are the signs of chiller malfunctions?Chiller malfunctions often manifest as reduced efficiency, abnormal noises or vibrations, excessive energy consumption, and temperature fluctuations. These symptoms should be carefully monitored for timely intervention.

- What should I consider when choosing a chiller service?When selecting a chiller service, pay attention to the provider’s experience, references, and offered warranties. Customer service and emergency response times should also be considered.